Alistair Potter's RC plane tips.

The Pilatus 'Hi-Top' - Frankenplane3

Back to planes list. Back to homepage.

Wingspan – 840mm / 31.5 inches.

Length – 600mm / 23.5 inches.

AUW – 670 grams / 23.6 ozs.

Drive – 1700Kv motor with 7 x 4 prop.

The more 'eagle-eyed' among you will instantly spot about 90% of my Pilatus Porter build. It was such a 'squirrelly' plane to fly it was more survival than flying - no fun at all! I decided to make some changes. Initially I was looking to build a kind of STOL aircraft, but the way it's turned out my flight speeds are nowhere slow enough.

So, what did I do?

First I increased the wing area. I did this by simply grafting-on some extra foam board.

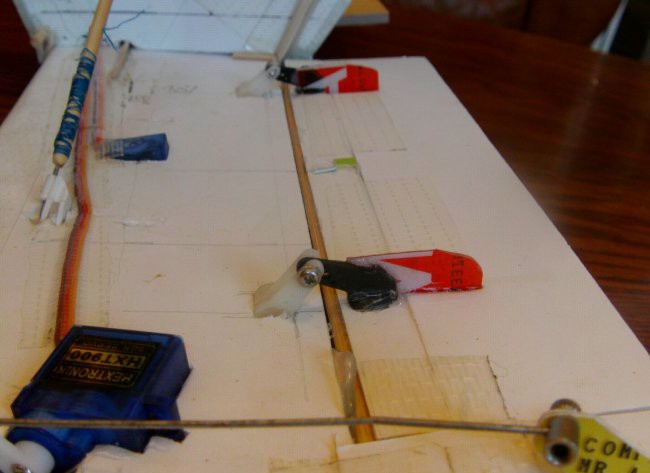

There is an extra piece of foam added where the ailerons used to be, and then the ailerons were simply taped to that. The only change needed was to extend the aileron servo control rods. I did a little shaping on the filler piece and the aileron at the outer edge of the wing to make them less vulnerable. I added extra foam to the existing flaps, which makes them pretty humongous. I've been trying them at a fairly shallow angle, but I'll push them down bit-by-bit until I get maximum lift and still have the plane controllable. I trimmed-off some of the Pilatus horizontal stabiliser detail to make it more of a visual 'fit' for the new plane and added a new rudder.

Here's the underside of the wing showing the flap hinges, and the red 'Ikea family card' reinforcing plates I added to stiffen the flap and help spread the load away from the original hinge attachment point.

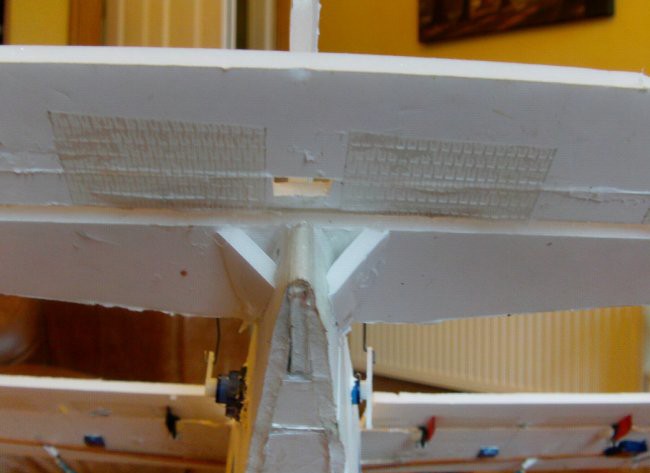

I wondered if some of the 'squirrelly' behaviour was due to the horizontal stabiliser flexing. The fuselage is very narrow at this point, so I added a triangular fillet each side to stiffen this area.

Here they are from the rear. Just two long triangles, with a steep bevel on the long edges to get good contact to the fuselage and horizontal stabiliser.

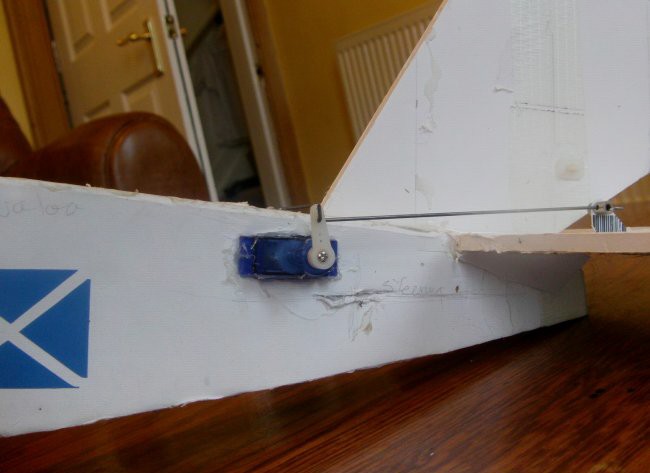

I also wondered if some of the odd behaviour might be due to flex in the control rods, so I remounted the servos on the fuselage near the tail. I also replaced a servo which I suspected might be causing problems.

Rudder…

…and elevator.

The fuselage leant itself to the simple mod of adding a raised cabin structure…

OK, the join is pretty dodgy, but it's a good fit of new to old!

View from the rear. I tried to keep most of the original fuselage intact - which is why the 'cabin is such a funky shape. A bit of the model 'A' Ford there I think?

Black sticky-back plastic to fake-up some windows helps a bit…

…and the view from the back.

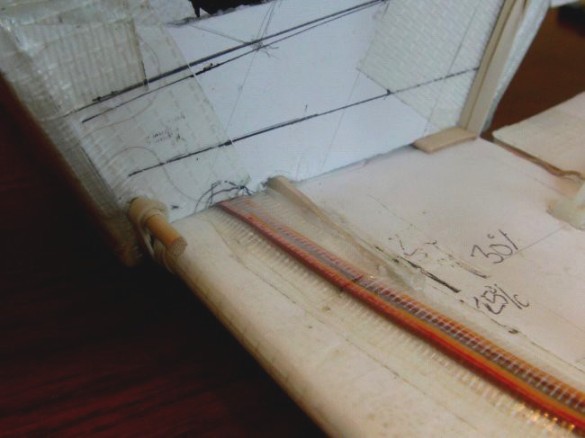

Once I got it all together I found the plane was doing that 'leaf waving' thing - which pointed to too steep an angle of incidence. I'd forgotten to take account of the undercamber I'd added to the wing when I cut the wing seating on the top of the cabin. I'm still in the process of fine-tuning the angle, and you can just see a tongue depressor slid between the wing and the fuselage to lift the back of the wing a little more and reduce the angle of incidence. Flattening the angle of incidence has made a vast difference to the flight characteristics. I must be down to about 1.5 to 2.0 degrees of incidence.

You might also notice a little wooden bar alongside the servo wires. This was a retrofit dihedral. The wing was flat, but I reckoned it might be better with dihedral. I slit the underside of the wing along the centreline and opened it up. I then made a slit alongside the embedded foam spar and glued an 'on-edge' tongue depressor into the wing. It stuck up a bit, but was simple to shave down. Once the reinforcing spar had set, I filled the centreline gap with hot glue and taped over the join. (This will never be the lightest of planes.)

I re-used my wing spars, by snipping off the original wire ends and binding them on to BBQ skewers with CA and thread.

Here's the inboard end of the spar. The floor pan of the fuselage is a foam and wood (MDF) sandwich, which allows for bolting-on structural goodies like the spar mounts and the undercarriage saddle.

Wingspan - 840mm 31.5 inches

Length - 600mm 23.5 inches

AUW - 670 grams 23.6 ozs

Power - 1700Kv motor with 7 x4 prop

OK, only its mother would love it, but the proof of the pudding is in the tasting, or flying in this case.

Below is a flight video. This is not the maiden, but the first test after changing the elevator servo and the receiver. Plus a few other mods to stiffen up the tail and reduce the angle of incidence. It does fly a bit better, but still has the inherent problem of levelling-out of a bank when too much elevator is applied. I've set my elevator throws to avoid that condition, but it means I don't have access to really tight banked turns.

I think if I rebuilt to this basic layout with new foam, I could knock a fair bit of weight off and get much closer to my STOL idea. I'd also lift and angle the tail to bring the horizontal stabiliser up higher and get that steep tail look a lot of the STOL aircraft have.

The other thing I've learnt is that the angle of incidence of these flat bottom armin-style wings (taken from the flat bottom) must be zero or close to zero for these faster-flying planes.